All pictures and diagrams are my own unless otherwise referenced

As part of the Mechanical Engineering program at NMT, I completed two years of capstone research projects. This included a semester of solar water heater design for a water purification system.

Our team designed a solar-powered collector to heat 500 gallons/day for a membrane distillation unit located near Farmington, NM. Our prototype achieved 300% increase in heat transfer over a previous model, and was approved to code.

My role in this project was prototype modeling, testing, and finite element analysis for model validation.

For a direct contact membrane distillation process designed by PESCO, an intake stream of hot water is necessary for functionality.

To maximize distillation efficiency, The complete system had a desired operating load of 500 gallons of water heated from ambient temperature to 50 degrees Celsius for 8 hours each day.

We designed a solar collector plate to be a thin channel with baffles to maximize heat transfer. After the plate was machined, a test plate was created with a plexiglass cover to analyze water flow through the solar collector.

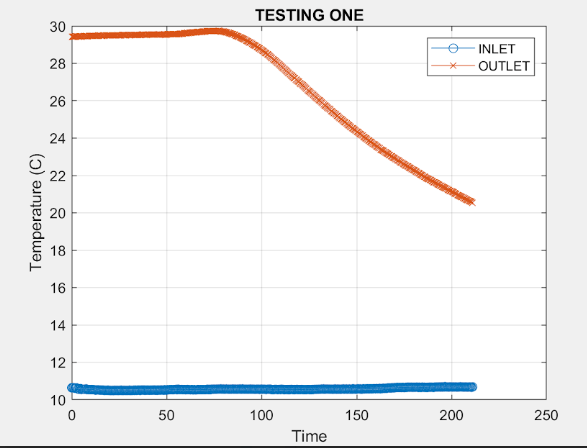

Transient heat transfer was experimentally and theoretically calculated through the collector plate, resulting in further iterations of the plate with more baffles.

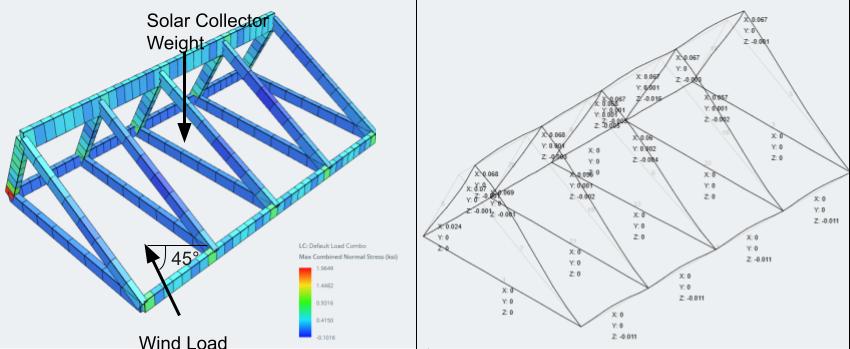

The solar collector was to be installed near Farmington, New Mexico for the DCMD process, so the solar collector frame needed to meet all relevant codes for ground-mounted solar collectors.

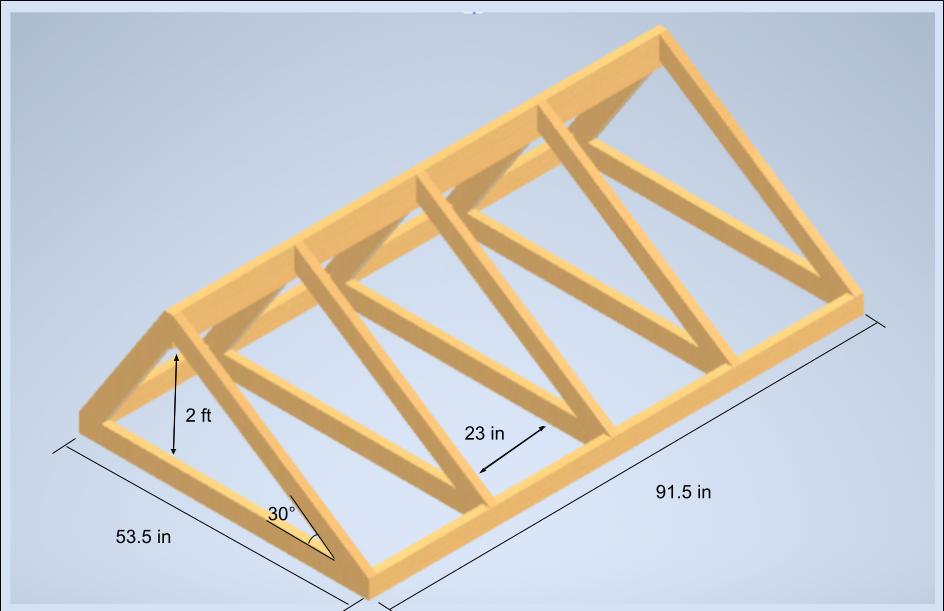

A wooden and steel frame was model in Inventor to be tested for each relevant AISC and ASCE code, with many iterations to each frame to reduce costs and maintain stability.

After procuring all the materials necessary, our team constructed the following wooden model of the solar collector, equipped with a transfer pump, pressure gauges, and thermostats for experimental measurements.

Leave a comment